The 2002 Ducati 998s Limited Edition Bostrom Race Replica features one of Ducati's most intricate factory paint jobs.

Repairs are even more challenging as the panels are carbon fiber.

Below are the steps taken to return a damaged panel to "better than factory finish".

What follows highlights the quality and effort that we put into every job that is undertaken at CCR.

Note: Click on the pictures to view a hi-res image and see the fine detail for each step of the process.

| |

|

The Challenge:

Having recently purchased one these rare bikes (only 155 were created), the customer wanted to return it to original condition.

As you can see, the previous owner inflicted various types of damage to the panel.

|

|

Prep of the damaged areas:

The first step required is to "feather edge" all of the damaged areas.

|

|

Serious Damage...Serious Prep:

Multiple colors and types of damage require various repair

techniques. Here I razor cut the clear coat around the Red area to

isolate the damage that spans the Red and Yellow layers.

|

|

Fill:

All low spots are now filled in.

Here you can also see another razor cut which is in the clear coat at end of the flame in lower

right hand corner.

|

|

Final Prep:

All filled areas are sanded and ready for paint.

Painstaking repair and preparation

is how each job is approached to insure a high quality finish.

|

|

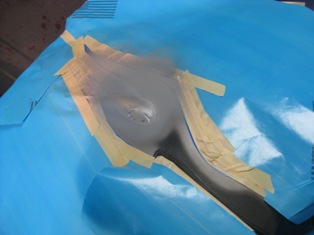

Painting:

Masking and Airbrushing in the "Yellow" layer.

|

|

Painting:

Airbrushing in the "White" layer

|

|

Painting:

Airbrushing in the "Blue" layer.

|

|

Painting:

Airbrushing in the "Gray" layer.

|

|

Painting:

Mask and spray the "Red" layer.

|

|

Color Painting Done:

Now ready to start the "clear coat' process

|

|

Clear Coating:

First application of multiple coats of the hi-solids clear.

|

|

Sand for Re-Clearing:

Now I must sand the repaired areas and build up enough clear layers to match

the clear I preciously razor cut.

|

|

The Finished Product

Panel has been re-cleared and wet sanded with 1500 grit to a completely flat finish which is BETTER than

Factory OEM from Ducati!

|

|